DTF Printing vs. Screen Printing: A Practical Comparison for Custom Apparel in Blairstown, NJ

Introduction

When choosing a method for custom t-shirt or garment printing, two of the most commonly used processes are Screen Printing and Direct-to-Film (DTF) Printing. Each has distinct advantages depending on project size, fabric type, design complexity, and budget.

In this guide, we’ll break down the key differences between the two methods and explain why more individuals, businesses, and organizations are considering DTF printing for their apparel needs.

How Screen Printing Works

Screen printing is a traditional method that involves pushing ink through a mesh screen (or stencil) onto fabric. A separate screen is required for each color, making it most efficient for large-volume orders with limited colors. It's typically used on cotton garments and is known for producing bold, solid prints with excellent opacity.

How DTF Printing Works

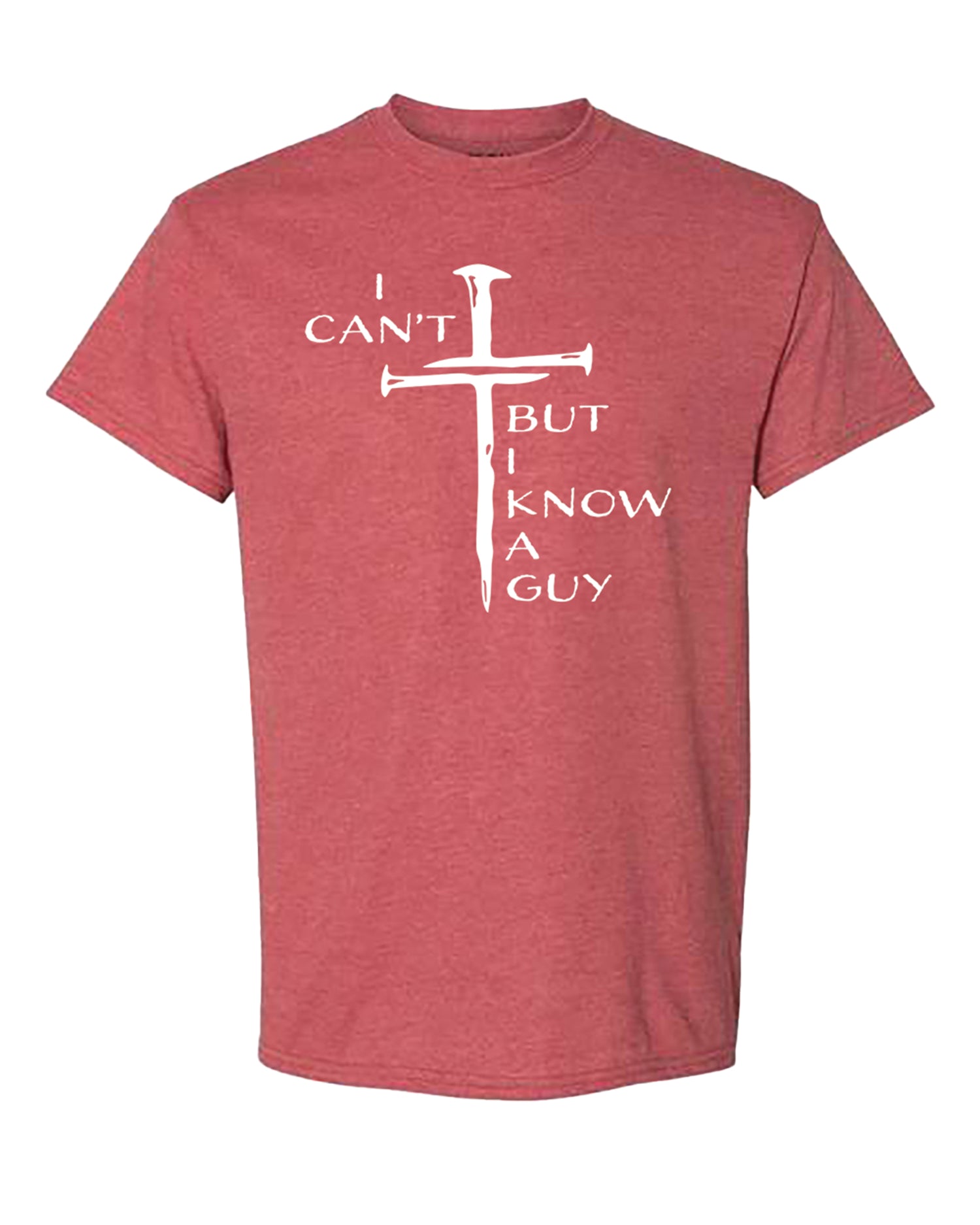

Direct-to-Film printing is a newer digital process. It begins with printing a design onto a clear PET film using specialized inks. The print is coated with a powdered adhesive and cured before being transferred to fabric using a heat press. This method works on a wide variety of materials, including cotton, polyester, blends, and synthetics, and produces full-color designs with fine detail and gradient capability.

Feature-by-Feature Comparison

| Feature | Screen Printing | DTF Printing |

|---|---|---|

| Setup Time | Requires screen preparation and color separation | Minimal; digital file is printed directly |

| Best Use Case | Large batches of simple designs | Short runs AND large batch for detailed, full-color prints |

| Fabric Compatibility | Mostly cotton and blends | Cotton, polyester, nylon, spandex, blends, and more |

| Color Range | Limited by the number of screens/colors | Unlimited full-color, photo-quality images |

| Print Detail | Bold, solid areas of color | Sharp detail, gradients, and fine lines |

| Durability | Very durable; may crack with age | Highly durable; flexible, retains color over time |

| Minimum Order Size | Often requires 12+ pieces for cost efficiency | No minimums; cost-effective for 1 to 10,000+ |

| Turnaround Time | Longer due to setup and drying | Generally faster, especially for small orders |

Considerations for Apparel Printing

The right printing method often depends on:

-

Quantity: Screen printing becomes cost-effective at higher quantities. DTF printing remains cost-effective, regardless of batch size.

-

Fabric type: DTF is more versatile, especially for synthetic or mixed fabrics.

-

Design complexity: Multi-color or photo-like prints are better suited to DTF.

-

Timeline: If you need shirts printed quickly, DTF generally has a faster turnaround.

-

Budget: Screen printing has setup costs; DTF avoids those. Paper Street Print Co ensures that our costs are the same, if not better, than screen printing.

Summary: Which Printing Method is Right for You?

Both DTF and screen printing have their place in the apparel industry. Screen printing is well-suited for bulk orders of simple designs on cotton fabrics. DTF offers greater flexibility, faster production for short runs, and compatibility with a broader range of garments.

For individuals, small businesses, event organizers, or schools looking for full-color, low-quantity, or quick-turnaround apparel, DTF may be the more practical option.

Local Printing with Paper Street Print Co

Paper Street Print Co offers both experience and equipment for high-quality DTF printing in Blairstown and throughout Warren, Sussex, and Northampton Counties. Whether you're printing 1 shirt or 10,000, we help you choose the method that suits your project.

Request a quote or contact us to get started.